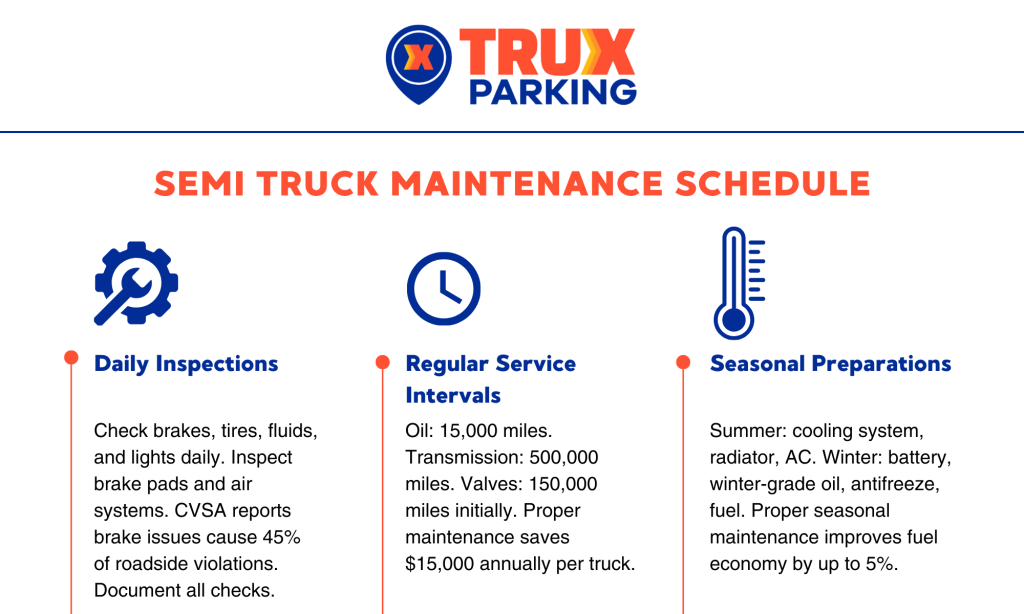

The Short Answer: Semi truck maintenance involves 3 key areas:

- Daily Checks: Quick visual inspections of brakes, tires, fluids, and lights

- Regular Service: Scheduled maintenance at specific mileage intervals (oil changes, filters, belts)

- Documentation: Keeping detailed maintenance logs to track issues and service history

Using this guide, you’ll learn exactly what to check, when to check it, and why each inspection point matters for your truck’s longevity and performance.

EXPERT INSIGHT: “Well-maintained commercial vehicles have a 26.5% lower breakdown rate and up to 20% better fuel efficiency compared to poorly maintained fleets.” — American Transportation Research Institute (ATRI), 2023 Operational Costs Report

For professional truckers and fleet operators, proper semi truck maintenance isn’t just about avoiding breakdowns — it’s about protecting a substantial investment and ensuring safety on the road. Research shows that proactive maintenance can reduce annual operating costs by up to $15,000 per truck while significantly decreasing the risk of accidents and costly roadside repairs.

Whether you’re an owner-operator or fleet manager, implementing a systematic maintenance program is crucial – neglected maintenance typically costs 3-4 times more than preventive care and can lead to catastrophic failures that threaten both safety and profitability.

Daily Inspection Checklist

A comprehensive daily semi truck inspection is critical for safety and DOT compliance, covering brakes, tires, fluids, and safety systems. These inspections, performed during pre-trip and at each stop, prevent breakdowns and costly repairs while ensuring maximum uptime.

REGULATORY CITATION: The Federal Motor Carrier Safety Administration (FMCSA) requires pre-trip inspections under 49 CFR § 396.13, with specific components that must be examined before each trip.

Quick Reference Maintenance Schedule

| Component | Every Stop | Daily | Weekly | Monthly | Miles/Time Based |

| Brakes | ✓ | ✓ | – | – | Service: 150,000 miles |

| Tires | ✓ | ✓ | – | – | Rotation: 50,000 miles |

| Engine Oil | – | ✓ | – | – | Change: 15,000 miles |

| Coolant | – | ✓ | – | – | Flush: 750,000 miles |

| Power Steering | – | ✓ | – | – | Filter: 150,000 miles |

| DEF | – | ✓ | – | – | Service: 150,000 miles |

| Air System | ✓ | ✓ | – | – | Filter: 150,000 miles |

| Battery | – | ✓ | – | ✓ | Service: 6 months |

| Lights | ✓ | ✓ | – | – | As needed |

| Windshield | – | ✓ | – | – | As needed |

| Emergency Equipment | – | ✓ | – | ✓ | As required by DOT |

Pre-Trip Essentials (Check Daily)

Brake System (Check Every Stop – Critical for Safety)

- Brake pad thickness (minimum 4/32″ for steering axle, 2/32″ for others)

- Air leak check during 360-degree walk-around

- Air pressure buildup time (85-100 PSI within 2 minutes)

- Maximum air loss test (no more than 3 PSI per minute with brakes applied)

SAFETY STATISTIC: According to the Commercial Vehicle Safety Alliance (CVSA), brake-related violations account for approximately 45% of all out-of-service conditions during roadside inspections.

Tire Inspection (Check Every Stop – Prevents Blowouts)

- Tread depth measurement (4/32″ minimum on steering tires, 2/32″ on others)

- Cold tire pressure check against manufacturer specs

- Visual inspection for cuts, bulges, uneven wear

- Lug nut tightness and wheel component inspection

Fluid Level Checks (Check Daily and Monitor During Operation)

| Fluid Type | Check Frequency | Why It’s Critical |

| Engine Oil | Daily/Cold Engine | Prevents engine failure |

| Coolant | Daily | Prevents overheating |

| Power Steering | Daily | Ensures safe steering |

| Washer Fluid | Daily | Maintains visibility |

| DEF | Each Fill-up | Emissions compliance |

| Brake Fluid | Daily | Safety critical system |

MANUFACTURER INSIGHT: According to Cummins Engine Company, over 45% of engine failures can be traced to cooling system issues, while another 25% relate to improper fluid maintenance.

Visual Inspection Items (Every Pre-Trip and Stop)

Lighting Systems

- Headlights (high/low beams)

- Turn signals (front/rear)

- Brake lights

- Marker lights

- Emergency flashers

- Reflectors

Windshield Components (Daily Check)

- Glass condition

- Wiper blade wear

- Washer system function

- Wiper operation coverage

- Defroster operation

Body/Frame Components (Daily Visual Inspection)

- Body panel damage

- Fairing/mud flap security

- Mirror adjustment/condition

- Door seal/latch operation

- Step/handle security

- Frame integrity

Safety Systems (Check Daily)

Air System Components

- Air pressure buildup time

- Warning system function

- Air dryer operation

- Gladhand condition

- Air line integrity

- Tank drainage

Emergency Equipment (Daily Verification)

- Fire extinguisher charge

- Warning triangles/flares

- Spare fuses

- First aid kit

- Flashlight function

- Cell phone charge

Documentation (Keep Current and Accessible)

- Registration

- Insurance cards

- Medical card

- Valid CDL

- Updated logbook

- Inspection reports

- Emergency contacts

Remember: Consistent daily inspections prevent breakdowns, ensure safety, and maintain DOT compliance while maximizing your driving time and profitability.

Critical Maintenance Intervals

Short-Term Service Points

Regular maintenance at short intervals is crucial for keeping your semi truck running safely and efficiently. Oil changes should be performed every 15,000 miles under normal conditions or 10,000 miles for severe duty. Replace oil filters with each oil change, and conduct air filter inspections monthly, replacing as needed or at 12-month intervals. Daily lubrication checks of key components like fifth wheels, door hinges, and steering linkages are essential for preventing wear.

TECHNICAL REFERENCE: The Technology & Maintenance Council (TMC) of the American Trucking Association recommends in their RP 334A that oil analysis should be performed at each oil change interval to identify potential engine problems before they cause catastrophic failures.

| Component | Normal Service Interval | Severe Duty Interval | Inspection Method |

| Engine Oil | 15,000 miles | 10,000 miles | Check dipstick level and oil condition |

| Oil Filter | Every oil change | Every oil change | Replace with manufacturer specified filter |

| Air Filter | 12 months or as needed | 6 months | Visual inspection, replace if dirty |

| Lubrication Points | Daily | Daily | Grease until fresh grease appears |

Medium-Term Maintenance

Brake system inspections should occur during every pre-trip check, with professional service every 15,000-20,000 miles. Listen for air leaks and check brake pad thickness—federal regulations require minimum 4/32-inch tread on steer tires and 2/32-inch on others. Transmission maintenance includes fluid and filter replacement at 500,000 miles or 60 months, whichever comes first. The cooling system requires attention every 300,000 miles for filter replacement, with a complete flush recommended at 750,000 miles.

INDUSTRY STANDARD: The Society of Automotive Engineers (SAE) J2833 standard establishes guidelines for commercial vehicle transmission fluid change intervals based on operational factors including duty cycle and environmental conditions.

| System | Service Interval | Key Checkpoints | Required Standards |

| Brakes | 15,000-20,000 miles | Air leaks, pad thickness | No leaks, legal pad thickness |

| Transmission | 500,000 miles/60 months | Fluid level, filter condition | OEM specified fluid level |

| Cooling System | 300,000 miles (filter) | Coolant level, leaks | Proper coolant concentration |

| Tires | Pre-trip inspection | Tread depth, pressure | 4/32″ steer, 2/32″ drive tires |

Long-Term Service Items

Major component overhauls follow specific mileage milestones. Valve adjustments should occur at 150,000 miles initially, then every 300,000 miles under normal conditions or 200,000 miles for severe duty. DPF filters need cleaning or replacement at 400,000 miles (250,000 for severe duty). The differential oil replacement schedule is set at 250,000 miles for normal duty and 150,000 miles for severe conditions. Preventive repairs like fan belt replacement should be done at 300,000-mile intervals, with more frequent inspections to catch wear before failure.

FLEET DATA: According to FleetNet America’s Quarterly Benchmarking Report, fleets that adhere to manufacturer-recommended long-term maintenance intervals experience 37% fewer roadside breakdowns related to major systems.

| Component | Initial Service | Normal Interval | Severe Duty Interval |

| Valves | 150,000 miles | 300,000 miles | 200,000 miles |

| DPF Filter | N/A | 400,000 miles | 250,000 miles |

| Differential Oil | N/A | 250,000 miles | 150,000 miles |

| Fan Belt | N/A | 300,000 miles | 150,000 miles |

Seasonal Maintenance Requirements

Summer Preparation

In hot weather, the higher temperatures put extra stress on truck parts. The heat makes coolant levels drop more quickly as it expands and evaporates. It also breaks down oil and rubber parts faster than usual, which can lead to problems if not checked regularly.

CLIMATE RESEARCH: A study by the North American Council for Freight Efficiency (NACFE) found that proper seasonal maintenance can improve fuel economy by up to 5% during extreme temperature conditions.

Your cooling system needs thorough inspection every 150,000 miles, with more frequent checks during hot weather. Here’s what to monitor:

- Pressure test the radiator system

- Check coolant levels and condition daily

- Inspect belts and hoses for cracks or wear

- Clean debris from radiator fins monthly

The AC system requires special attention with:

- Annual refrigerant level checks

- Condenser cleaning every 3 months

- Belt tension verification monthly

- Cabin filter replacement every 50,000 miles

Winter Readiness

During winter, cold weather causes truck parts to shrink and makes fluids thicker. The cold also slows down the battery’s ability to work properly. All of these changes affect how well your brakes work and how electricity flows through the truck, which is why special winter maintenance is so important.

TECHNICAL INSIGHT: The American Petroleum Institute (API) recommends specific winter-grade oil specifications for commercial vehicles operating in temperatures below 15°F to ensure proper engine lubrication during cold starts.

Battery care becomes critical:

- Load test batteries every 6 months

- Clean terminals and check connections monthly

- Keep batteries fully charged in cold weather

- Replace batteries showing signs of weakness

Fluid requirements change with temperature:

- Switch to winter-weight oil as recommended

- Maintain proper antifreeze concentration

- Use winter-grade diesel fuel

- Keep fuel tanks full to prevent condensation

Weather-Specific Checks

Temperature changes make truck parts expand and shrink, while different air temperatures can affect tire pressure and how well the brakes work. Knowing how these basic changes affect your truck helps you plan when to do maintenance.

Tire maintenance is crucial:

- Check pressure during temperature changes (cold mornings)

- Maintain 4/32″ minimum tread on steer tires

- Inspect for weather-related damage daily

- Adjust pressure according to load and temperature

Safety equipment becomes seasonal:

- Test defrosters before cold weather

- Replace wiper blades twice yearly

- Keep washer fluid rated for temperature

- Verify all lights and reflectors monthly

Remember that prevention is always cheaper than repair. Regular seasonal maintenance not only extends your truck’s life but also ensures safer operation in all weather conditions.

The Road to Reliability

A well-maintained semi-truck helps you make more money and stay safe on the road. This checklist isn’t just paperwork—it’s your guide to keeping your truck running, saving money, and staying safe mile after mile.

ECONOMIC IMPACT: The Owner-Operator Independent Drivers Association (OOIDA) reports that preventive maintenance programs typically deliver a 3:1 return on investment through extended equipment life and reduced downtime.

Key Takeaways:

- Prevention Saves Money: It costs 3-4 times less to prevent problems than to fix them after they happen. Following this checklist can save you up to $15,000 each year per truck while preventing breakdowns on the road.

- Three-Step Maintenance Plan:

- Daily Checks: Look over your truck each day to catch small problems early

- Regular Service: Follow the manufacturer’s schedule to make parts last longer

- Seasonal Prep: Get your truck ready for hot and cold weather to protect it year-round

- Keep Good Records: Maintenance logs aren’t just for DOT inspections—they help you track problems and plan your maintenance better.

- Safety Comes First: Checking tires and brakes at every stop isn’t just a good idea—it saves lives, including yours.

- Know When Parts Need Service: Understanding when to service or replace major parts helps you plan your budget and avoid surprise breakdowns.

Taking Action:

Put this checklist to work by:

- Creating a log book for each truck

- Setting reminders for service due dates

- Teaching all drivers how to do proper inspections

- Finding good mechanics you can trust

- Looking at your maintenance records every few months to spot patterns

MAINTENANCE MANAGEMENT: The Federal Motor Carrier Safety Administration (FMCSA) found that vehicle-related factors contribute to approximately 10% of all truck crashes, with most being preventable through proper maintenance.

Remember: Your semi-truck is your business partner on the road. Every minute you spend on maintenance gives you hours of driving time and years of reliable service. By following this simple approach to truck care, you’re protecting your job and your future on the road.

How TRUX Helps Truck Drivers on the Road

With a quickly expanding nationwide network of secure truck parking lots, TRUX helps drivers across the US meet their business goals. In addition to security and excellent customer service, we also have an on-site diesel mechanic at select TRUX locations so you can focus on the drive.

Find TRUX Parking locations in these states: