At a Glance: Proper construction equipment storage protects machinery from theft, corrosion, and operational downtime. Using secure outdoor locations and applying a structured preparation process helps prevent damage and keeps equipment ready for fast redeployment during construction projects.

Every piece of construction equipment represents a major investment for a construction company. Machines work through heat, dust, and heavy workload cycles, and improper storage can accelerate wear even when equipment is not running. Exposure to unstable parking surfaces or unsecured lots can reduce reliability and increase repair frequency.

A secure storage lot gives equipment owners peace of mind by providing a safe, organized space for their equipment, keeping it out of the way while protecting it from unnecessary damage. It provides organization and security when equipment transitions between phases of work. When projects move, pause, or rotate crews, having a dependable place to store equipment keeps operations stable. This guide reviews how to maintain performance and safety through proper outdoor storage practices.

Why Proper Storage Matters

Storing equipment for any extended period introduces wear concerns that can be managed through consistent controls and preparation. Without a consistent process, equipment may deteriorate faster than expected, affecting availability when work resumes.

Benefits of proper storage:

- Protects hydraulic seals, hoses, and engine systems from corrosion

- Reduces risk of theft or tampering in remote or busy work zones

- Keeps equipment organized between projects and phases of work

- Helps maintain predictable maintenance schedules

- Supports documentation that simplifies inspections and redeployment

A consistent storage plan helps preserve each valuable asset and reduces preventable downtime. Proper storage also reduces the strain on on-site personnel. Equipment that is organized, documented, and stored safely requires less troubleshooting when returning to service. This improves workflow once the equipment is needed again on the next job.

Equipment That Requires Secure Outdoor Storage

Contractors manage a wide range of machines. Some are used daily, while others support specific project phases. Storing them on stable ground with clear spacing helps maintain safety and organization.

Common heavy equipment and attachments stored outdoors include:

- Excavators, bulldozers, and grading units

- Wheel loaders for material handling

- Skid steers that support both large and compact sites

- Dump trucks and hauling units

- Booms and lift equipment for elevated work

- Power units such as generators and compressors

Proper spacing helps operators move in and out of the yard without the risk of accidental scraping or impact. It also improves visibility when coordinating pickup and transport schedules. Clear organization supports faster deployment from the storage yard to the field.

Outdoor vs Indoor Storage Considerations

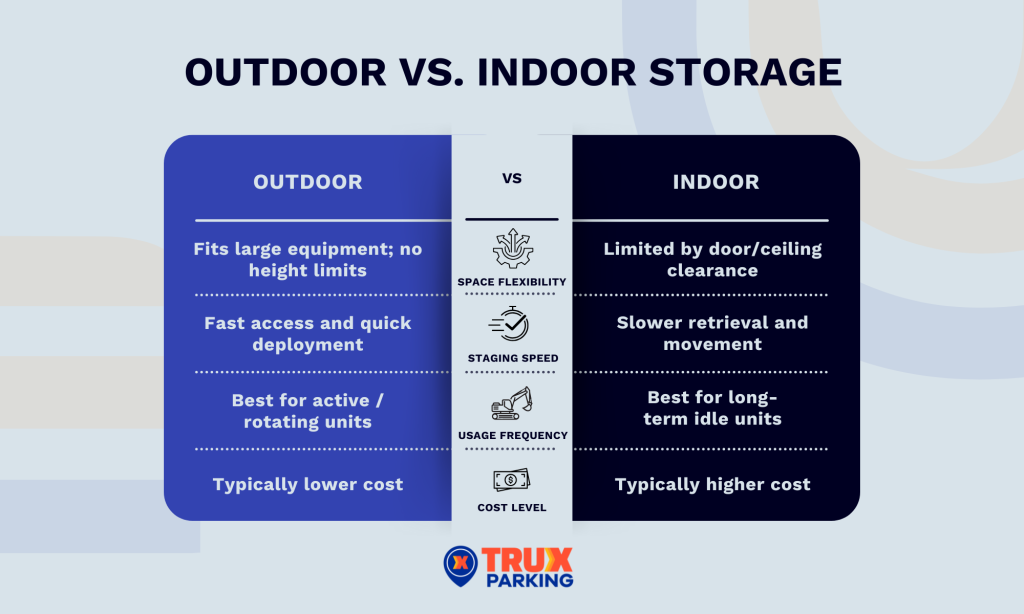

Outdoor and indoor storage serve different operational needs. The right choice depends on rotation frequency, equipment size, and how soon the unit will be placed back into service.

Outdoor yards are often preferred when movement and accessibility matter. Indoor storage is used when equipment remains inactive for longer periods. Indoor storage can also have limitations. Door heights, ceiling clearance, and turning room may restrict certain machines. Some indoor facilities also present higher overhead costs or limited access for delivery vehicles. Understanding these tradeoffs helps teams select the most effective parking approach for each unit. Both storage types support operations, but outdoor yards commonly offer more flexibility for equipment that moves often.

Preparing Construction Equipment for Outdoor Storage

Preparation protects systems that experience stress even when not running. A clear and repeatable process helps heavy machinery return to service smoothly.

Preparation steps before outdoor storage:

- Rinse off mud, dust, and construction materials to prevent moisture trapping

- Refill or replace engine fluids and coolant as needed

- Lubricate joints, cylinders, and pivot pins

- Disconnect or maintain battery charge during downtime

- Lock cabs and control access points

- Position the equipment on level ground to avoid flat spots on tires

- Secure attachments to prevent shifting

- Log storage date and current usage hours

Label equipment rows or storage lanes so teams can locate units quickly when planning deployment. Clear organization supports reliable retrieval and transfer to the next construction site or job site. A consistent preparation process supports proper storage during long-term storage or short-term downtime.

Choosing Secure and Compliant Lots for Equipment Storage

When selecting a lot to store your equipment, it’s important to prioritize security and compliance. Look for lots with strong security features to protect your equipment from theft, damage, and unauthorized access..

Security measures for safe outdoor storage:

- Choose lots with fencing and controlled entry gates

- Select locations with adequate lighting for nighttime visibility

- Look for lots with surveillance cameras covering travel lanes and machinery rows

- Ensure there’s a check-in and check-out log for operators and vehicles

- Opt for lots that offer telematics or asset monitoring devices, when necessary

Choosing the right lot with the right security and compliance measures ensures your equipment is protected and helps maintain smooth, accountable operations.

How to Choose the Right Outdoor Storage Location

Selecting the right place to park equipment influences efficiency and workload coordination. Contractors benefit from selecting a location that supports movement and staging.

Qualities of a strong outdoor yard:

- Surface is durable enough for heavy equipment storage

- Wide turning radius for haulers and trailers

- Lighting and security features to deter unwanted activity

- A convenient location that provides easy access to major travel routes

- Drainage that directs water away from parked units

- Defined travel lanes for loading and unloading

Map the yard layout so supervisors can assign specific rows for particular unit types. This supports faster staging and reduces confusion during mobilization. A well-organized outdoor storage yard supports steady movement between work phases.

TRUX Parking: Outdoor Storage Built for Construction Equipment

TRUX Parking provides a contractor storage solution designed for valuable equipment that rotates between jobs. Each lot includes reinforced surfaces, reliable monitoring, and security measures configured for large equipment. The yard layout supports safe maneuvering while keeping equipment clearly arranged.

Locations near major highways help general contractor crews move equipment with minimal travel time. Crews can place equipment in storage during project transitions and retrieve it when needed for the next construction phase. The reservation process is straightforward and designed for field teams.

Reserve outdoor storage with TRUX Parking today to keep your equipment organized, protected, and ready for deployment.

Visit our secure facilities in:

- Georgia

- Texas

- Idaho

- Mississippi

- Oklahoma

- Ohio

- Utah

- Pennsylvania

- North Carolina

- Florida

- Oregon

- Nevada

- South Carolina

Reserve your spot with TRUX Parking and store your equipment in a monitored outdoor yard designed for easy access and reliable staging.